The lost wax casting method is an ancient handicraft and a modern technology, mainly used to make bronzes and other ancient cultural relics.

The principle of the lost wax casting method is to apply wax liquid on the surface of copper or other metal materials, and then put the wax mold into a high-temperature furnace to melt it and form a wax film. At this time, the melted wax film is brought into contact with copper or other metal materials, and the surface of the wax film will melt due to high temperature, forming many small points to form a casting mold. Then, take out the casting mold, add some more metal to the remaining wax liquid, heat the casting mold to melt it, and mix it with the remaining wax liquid to form a new casting mold.

Now, the lost wax casting method has developed into a modern technology and is used in many fields, such as making molds for industrial products such as automobiles, airplanes, and ships, as well as the casting of ancient cultural relics.

Bronze sculptures still use the lost wax casting method, which is slightly different from the traditional process.

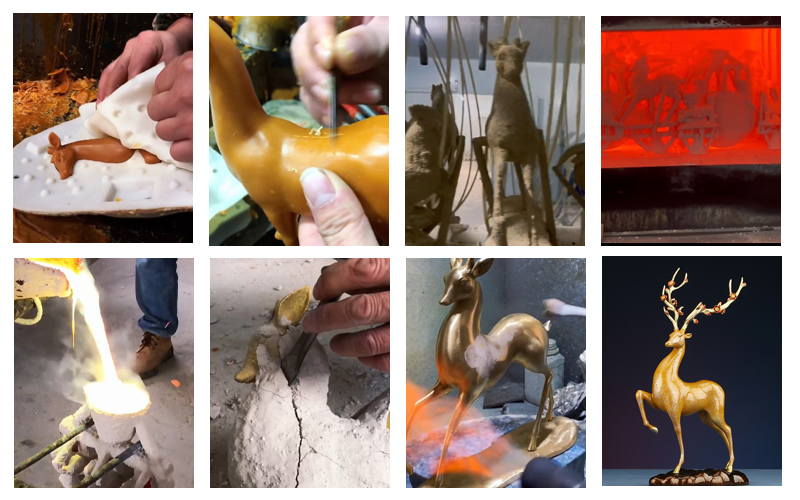

After the clay model or 3D printing model is confirmed, a silicone mold will be manufactured at a 1:1 ratio.

Silicone mold is a material with high elasticity and toughness, and has good heat resistance, cold resistance, aging resistance and other characteristics. It can easily reproduce products of various complex shapes, has a long service life and is easy to clean and maintain. In addition, silicone molds are also environmentally friendly and will not pollute the environment. They are widely used in food, medical, cosmetics, electronics and other industries.

According to the silicone mold, a wax model is made and the wax model is repaired to maximize the design details.

A sand shell is made based on the wax model. After the sand shell is dried, it is put into a baking oven to melt the wax model and flow out. Then, copper water melted at high temperature is poured into the sand shell to obtain the same bronze shape as the melted wax model, which is then cooled and formed. The sand shell is then removed to obtain a bronze sculpture (or perhaps a part, as large sculptures will be divided into multiple parts to make).

The bronze statue is then welded, polished, repaired as needed, and finally painted to obtain the final work of art.

The application of lost wax casting method in the production of bronze sculptures

- Lisa

- October 19, 2023

- 4:28 pm

- No Comments

Lisa

Hi, I’m Lisa Cui, the founder of hbgreattree.com,

The purpose of this article is to share with you the knowledge related to bronze sculpture from a Chinese supplier’s perspective.

All articles

Facebook

Twitter

LinkedIn